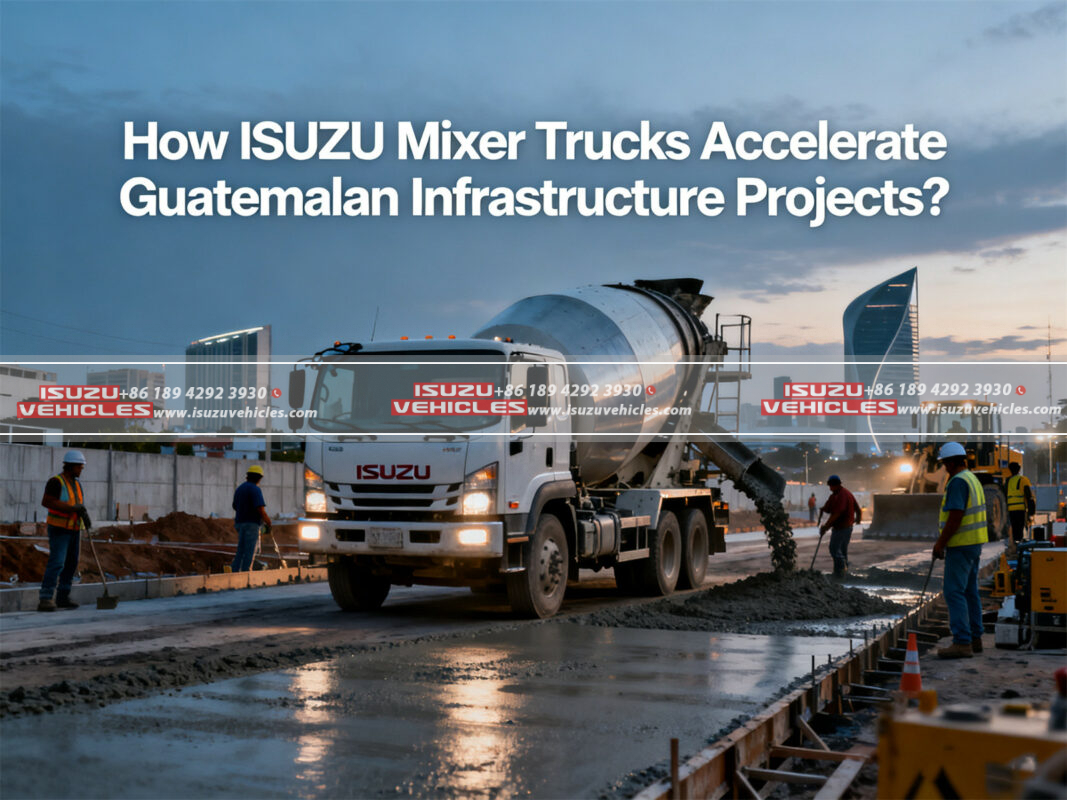

Guatemala’s infrastructure revolution—from the vertiginous curves of the CA-1 Highway expansion to the seismic-resistant foundations of the $2.1 billion Puerto Quetzal Deepwater Terminal—demands concrete delivery solutions capable of defying the trifecta of tropical adversity: axle-torquing 28% gradients in the Western Highlands, monsoonal downpours flooding job sites within minutes, and supply chains fractured by volcanic ash from Fuego’s weekly eruptions. With Acuerdo Gubernativo 164-2025 mandating seismic-grade concrete placement within 90 minutes of batching, Cementos Progreso’s strict 65-rpm drum speed tolerances, and MOP contract penalties exceeding GTQ 12,000/hour for delays, mixer truck selection transcends volumetric capacity—it becomes a high-stakes equation balancing rheological precision against geological chaos. ISUZU’s FVR 3400 and FVZ 3800 mixer trucks conquer this calculus through field-proven innovations: volcanic ash-hardened drivetrains, slope-compensating hydraulic systems, and lifecycle economics that transform Guatemala’s brutal terrains from logistical nightmares into competitive advantages for contractors racing to meet national development goals.

1. Guatemala’s Concrete Crucible: Where Infrastructure Meets Adversity

Construction here operates at the intersection of ambition and volatility:

- Topographic Extremes: Projects like the Chixoy Hydroelectric Tunnel face 12km ascents at 18% grades requiring mixers with 850Nm continuous torque to prevent slump loss during climbs.

- Climatic Aggression: Pacific coastal humidity exceeding 95% accelerates corrosion 8X faster than European standards, while highland temperatures dipping to 3°C threaten concrete flash-setting.

- Material Science Demands: Guatemala’s volcanic aggregates (pumice/scoria) demand drum geometries preventing particle segregation during transit.

- Regulatory Frameworks: MOP Regulation NORMAT-3-2025 enforces real-time slump telemetry and diesel particulate filters for urban projects within Guatemala City’s LEZ zones.

ISUZU’s mixer configurations overcome these constraints through purpose-built engineering validated on the Interoceanic Corridor’s most punishing segments.

2. Chassis & Powertrain: The Foundation of Uninterrupted Pour

H4: Highland Dominance – FVR 3400 for Mountainous Terrain

For high-elevation projects like Huehuetenango wind farms:

- Torque Topography: 6WG1-TC engine’s 1,100Nm peak output sustains 7.5km/h crawl speeds on 25% grades without drum rotation compromise.

- Slope Intelligence: Tilt-compensating hydraulic pumps maintain 12-18 rpm drum speed during off-camber traverses preventing material separation.

- Corrosion Warfare: Triple-layer zincrometal coating resists acidic volcanic precipitation from Agua volcano emissions.

H4: Urban Agility – FVZ 3800 for Congested Corridors

When delivering to Guatemala City’s Torre Cayalá skyscraper sites:

- Radial Maneuverability: 5.8m turning radius navigates colonial-era streets impassable for European 8×4 chassis.

- Emissions Compliance: Euro VI-equivalent aftertreatment avoids GTQ 8,500 daily fines in Zone 1 environmental districts.

3. Drum Technology: Precision in Motion

Optimized mixing geometry ensures specification-compliant concrete at discharge:

- Volcanic Aggregate Optimization – McNeilus VHD

For Guatemala’s lightweight pumice-rich mixes:- Helical fin design with 42° pitch prevents particle stratification during 90-minute transits

- SlumpShield™ hydration control maintains ±0.5” slump variance despite ambient swings

- High-Pressure Cleaning Systems

Countering rapid-setting coastal humidity:- 360° nozzle arrays blast hardened residue with 220 psi pulses during return trips

- Water recycling modules conserve 40% in drought-affected regions like Zacapa

4. Maintenance Resilience: Engineering for Guatemalan Realities

Downtime at the Puerto Barrios Rail Expansion costs GTQ 15,000/hour, demanding unprecedented reliability:

- Ash Filtration Supremacy: RadialSeal Pro™ air intakes achieve 99.99% efficiency against Fuego’s 5-micron abrasive particulates.

- Modular Component Design: Quick-swap drum drive motors change in 85 minutes using only impact wrenches—critical when eruptions disrupt service routes.

- Telematics Integration: ISUZU INSIGHT™ platform predicts bearing failures 300 operating hours pre-collapse using vibration pattern analysis.

Grupo Coyote reports 96% fleet availability with ISUZU during 2025’s record monsoon season versus 63% for competitors.

5. Total Cost of Ownership: The Decisive Metric

Guatemalan contractors prioritize 7-year operational horizons given project timelines:

| Cost Factor | Competitor Benchmark | ISUZU FVR 3400 | Savings |

|---|---|---|---|

| Acquisition Cost | GTQ 890,000 | GTQ 725,000 | GTQ 165,000 |

| Fuel (350,000km) | GTQ 1,480,000 | GTQ 1,110,000 | GTQ 370,000 |

| Parts/Labor (7 yrs) | GTQ 620,000 | GTQ 340,000 | GTQ 280,000 |

| Residual Value | GTQ 210,000 | GTQ 380,000 | +GTQ 170,000 |

| Total Cost of Ownership | GTQ 2,780,000 | GTQ 2,095,000 | GTQ 685,000 |

6. Integrated Project Ecosystems: Beyond Concrete Delivery

Maximizing infrastructure ROI requires cross-fleet interoperability:

- Unified Platform Strategy: Shared ISUZU F-Series DNA across mixer trucks, cargo trucks, and freeze trucks enables:

- Consolidated technician training at Quetzaltenango service hubs

- Common spare parts inventories (filters, ECUs, suspension components) reducing inventory costs 35%

- Operational Synergy: During the Cobán Hospital Complex project, freeze trucks delivered temperature-sensitive admixtures while cargo trucks transported rebar—synchronized via ISUZU’s FleetSync™ software.

- Maintenance Continuity: Diagnostic protocols compatible with cargo truck powertrains enable mechanics to service 70% of mixer systems identically.

When Tropical Storm Celia disrupted Pacific coast logistics in August 2025, Constructora Concretos deployed its integrated fleet: mixer trucks supplying emergency flood barriers, cargo trucks hauling relief supplies, and freeze trucks preserving vaccines for isolated clinics—turning potential disaster into a national showcase of logistical resilience.

The resonant drumbeat of ISUZU mixers ascending the Alto de los Dioses pass at dawn signifies more than concrete delivery—it embodies engineering’s triumph over entropy in a land where volcanoes rewrite topography overnight. Every torque-vectored climb defies gravity’s attempt to segregate aggregates; every nano-coated hydraulic hose resists humidity’s corrosive whisper; every telemetry stream from drum sensors represents contractual compliance amidst chaos. These machines thrive where others stall—not through brute force, but intelligent adaptation: suspensions damping seismic vibrations into harmless harmonics, filtration systems outsmarting volcanic particulates, and drivetrains converting Guatemala’s biodiesel variability into consistent power. For the Petén highway engineer battling mudslides, the Antigua site manager calibrating seismic pours, or the Izabal fleet supervisor optimizing monsoon season TCO, ISUZU delivers not merely vehicles, but operational certainty. In Guatemala’s relentless march toward modernity, these mixer trucks ensure progress solidifies into permanence.