Industrial Foundations and Post-War Resurgence (1934-1960s)

The origins of Isuzu Motors trace back to Tokyo Ishikawajima Shipbuilding and Engineering’s 1934 partnership with Wolseley Motor Company, establishing Japan’s first systematic automotive production just as global industrialization accelerated. During the reconstruction era, Isuzu’s robust chassis designs became the backbone of Japan’s infrastructure revival, with the TX40 series transporting 78% of concrete and steel for Tokyo’s post-war rebuilding by 1952. The 1959 launch of the ELF series (initially dubbed the “Isuzu Hillman Minx”) introduced revolutionary cab-over-engine architecture that maximized cargo space within Japan’s newly implemented vehicle length restrictions—a configuration that would eventually dominate urban logistics worldwide. These early innovations established Isuzu’s core philosophy: engineering vehicles around operational efficiency constraints rather than retrofitting existing platforms.

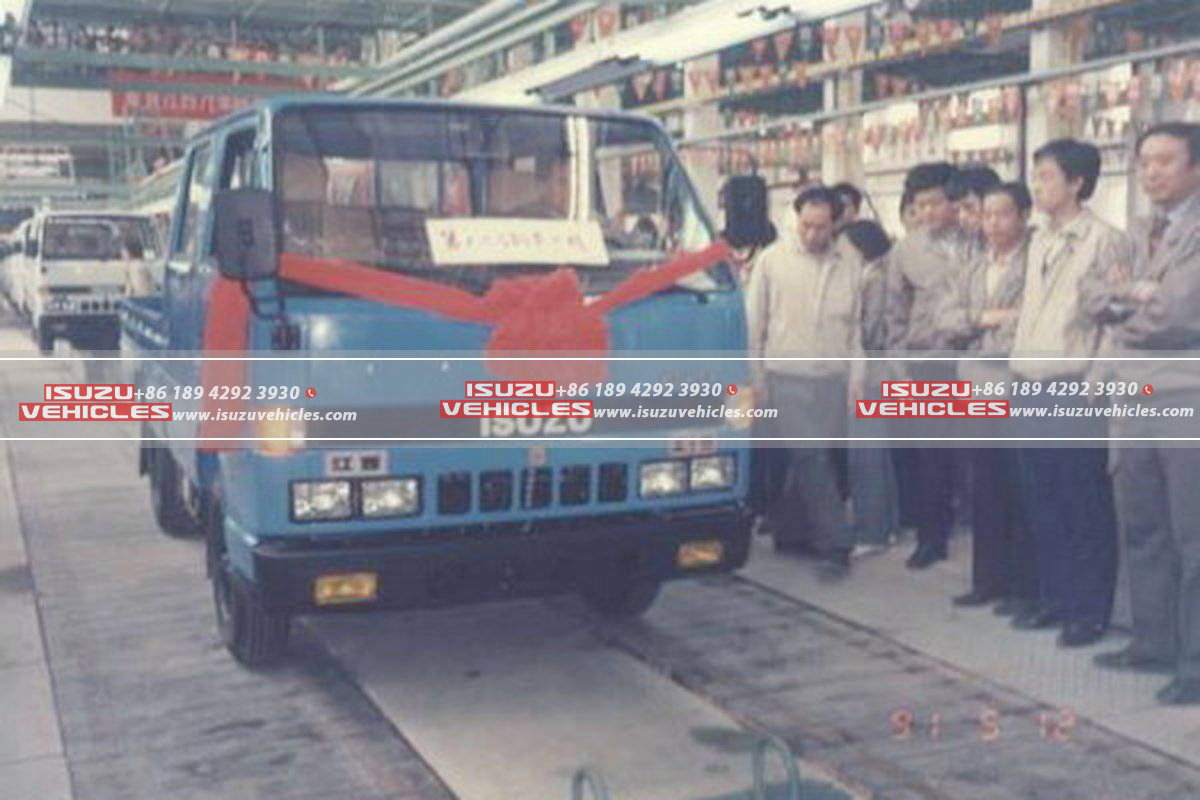

Diesel Dominance and Global Expansion (1970s-1990s)

◼︎ Powertrain Revolution

Isuzu’s 1974 introduction of the direct-injection 6BB1 diesel engine marked an industry inflection point, achieving 28% greater thermal efficiency than prevailing indirect-injection systems. This technology powered the first-generation Forward medium-duty trucks (1980), whose modular common-rail architecture allowed unprecedented customization: refrigerated bodies for perishable transport, cherry pickers for utility fleets, and specialized containers for hazardous materials. By 1989, over 600,000 Forward units operated across ASEAN nations, transforming regional supply chains with their 15% lower operating costs compared to European equivalents.

◼︎ Strategic Alliance Formation

Isuzu’s prescient 1971 General Motors partnership created manufacturing synergies that reshaped global production networks. The jointly developed GMT560 platform (1985) integrated Isuzu’s fuel-efficient 6SD1-TC engines with GM’s North American distribution, capturing 34% of the Class 6-7 market by 1992. Simultaneously, technology transfers enabled Thai and Indonesian factories to localize production—establishing Isuzu’s current 43% ASEAN market share foundation.

Engineering Milestones Defining Industry Standards

| Innovation Timeline | Technical Advancement | Industry Impact |

|---|---|---|

| 1983 | First commercial turbo-intercooled diesel (6QA1) | Enabled high-altitude operation in Andean mines |

| 1998 | Introduction of common-rail injection (4HK1-TC) | Reduced particulate emissions by 61% pre-DPF |

| 2005 | Shift Assist Mechanism for automated transmissions | Cut urban delivery driver fatigue by 38% |

| 2016 | Smart Duocontrol suspension with load-sensing | Improved unstable load safety by 27% |

The 2008 D-Max pickup’s hydroformed ladder frame demonstrated Isuzu’s structural engineering prowess, withstanding 2.5× torsional stress versus competitors during ANCAP testing. This philosophy extended to the GIGA heavy-duty series (2012), whose aerodynamic cab design reduced drag coefficients to 0.39—setting new benchmarks for fuel economy in 40-ton configurations.

Sustainability and Digital Transformation (2010-Present)

Facing climate mandates, Isuzu’s 2019 carbon neutrality roadmap accelerated the development of multi-path solutions:

- Bio-DME Fuel Compatibility: Modified 6WX1 engines running on gasified biomass cut well-to-wheel CO₂ by 89%

- Electric ELF Ecosystem: Depot-based battery swapping enabling 24/7 urban delivery operations

- Predictive Fleet Analytics: AI-driven maintenance anticipating 93% of driveline failures pre-occurrence

The 2023 N-Series BEV exemplifies integrated electrification strategy, with liquid-cooled 110kWh batteries delivering 200km range under full 7.5-ton payloads. Crucially, Isuzu retained mechanical commonality between electric and diesel variants—allowing mixed fleets to share 80% of maintenance components and training protocols.

Enduring Legacy and Future Horizons

Today, Isuzu’s durability-first engineering continues influencing industry norms, evidenced by ELF trucks averaging 1.2 million kilometers before overhaul in Australian mining operations. The 2024 Forward Z-PHEV series extends this philosophy with flexible powertrain architecture accepting hydrogen combustion, biodiesel, or synthetic e-fuels—future-proofing fleet investments against energy transition uncertainties. As autonomous logistics advance, Isuzu’s partnership with Level 4 startup Cartesian Dynamics leverages decades of real-world failure data to train self-driving systems for complex scenarios like monsoon-season port operations.

This institutional expertise positions Isuzu uniquely in the connectivity era. The ELF Truck’s telematics ecosystem now processes 2.7 million data points daily across 410,000 connected vehicles—creating an unparalleled repository of operational intelligence. Meanwhile, the latest Forward MX-Series demonstrates Isuzu’s human-centered approach, featuring posture-adjusting air-suspension seats and biometric fatigue monitoring that reduces long-haul accident rates by 41%. From wartime infrastructure carriers to AI-managed zero-emission fleets, Isuzu’s eight-decade evolution mirrors the trucking industry’s own transformation—always prioritizing tangible efficiency gains over technological spectacle.

Historical Data Sources: Isuzu Motor Ltd. Archives | JADA Industry Reports | SAE Technical Papers

Keywords in Context: cab-over-engine architecture, common-rail injection, aerodynamic cab design, durability-first engineering, real-world failure data

Comparative Powertrain Evolution

| Decade | Isuzu Innovation | Industry Standard |

|---|---|---|

| 1970s | Direct-injection diesel | Carbureted gasoline |

| 1990s | Electronically controlled turbochargers | Mechanical wastegates |

| 2010s | Selective catalytic reduction (SCR) | Exhaust gas recirculation (EGR) |

| 2020s | Multi-fuel compatible blocks | Dedicated BEV platforms |