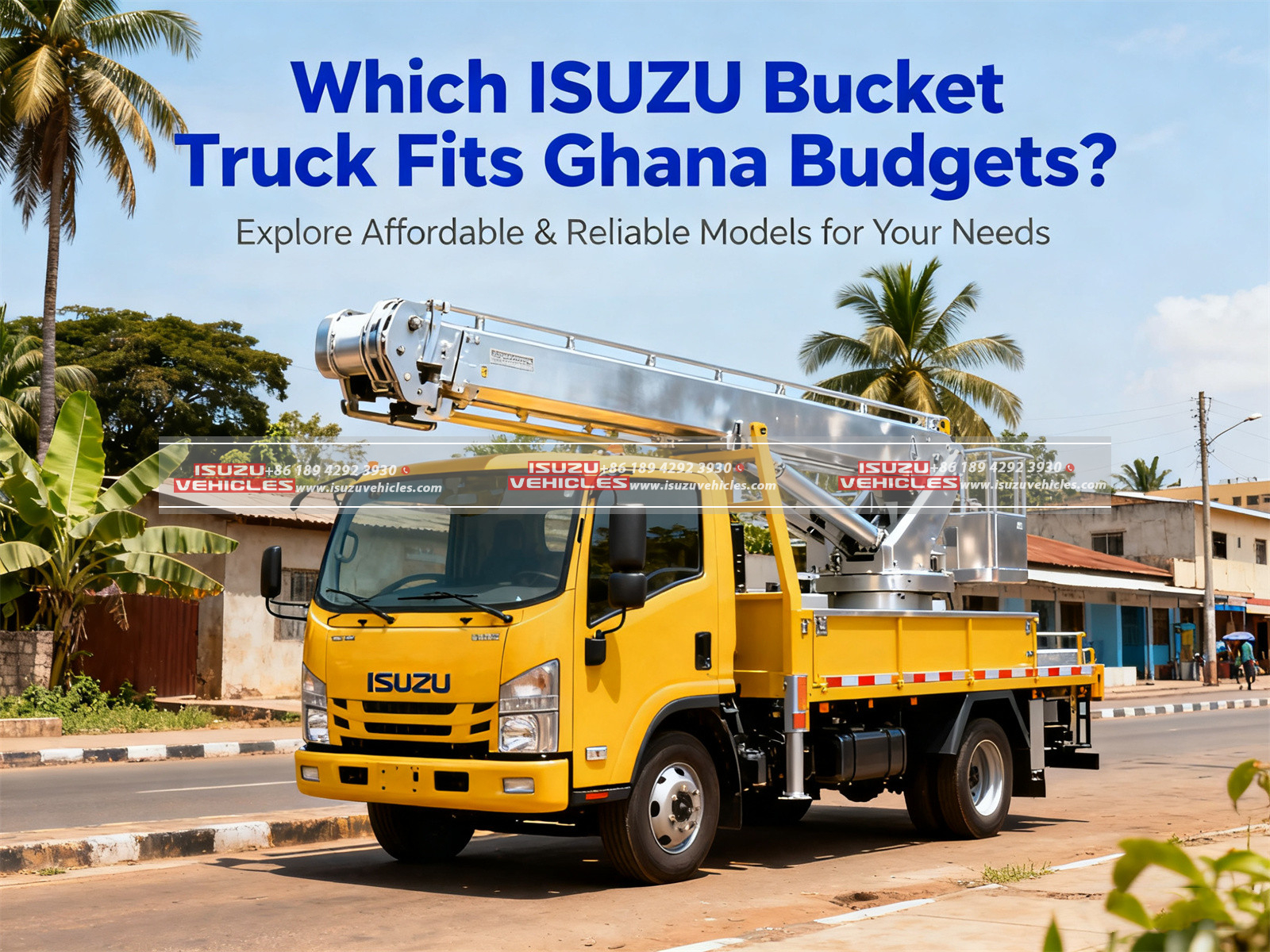

Ghana’s accelerating infrastructure development—from the 380kV Kumasi-Bolgatanga transmission line expansion to the nationwide 5G tower rollout and Accra’s relentless skyline growth—demands aerial work platforms capable of enduring equatorial humidity, laterite-road vibrations, and the relentless budget pressures facing ECG contractors and telecom SMEs. With import duties pushing 35% on commercial vehicles, diesel averaging GHS 14.20/litre, and roadworthy certifications requiring specialized modifications, selecting the right bucket truck transcends equipment choice—it becomes a strategic survival decision. ISUZU’s Ghana-optimized bucket trucks bridge this gap through locally assembled chassis, tropicalized hydraulic systems, and lifecycle cost engineering that transforms capital constraints into competitive advantages for utility crews and construction foremen navigating Ghana’s demanding terrain.

1. Ghana’s Operational Realities: Budget Pressures & Environmental Demands

Navigating Ghana’s unique economic and physical landscape requires purpose-built solutions:

- Fiscal Constraints: 30-40% upfront cost premiums for imported aerial platforms strain SME cashflow, making localized assembly at Japan Motors’ Tema plant critical for affordability.

- Climatic Aggressors: 85% humidity in Takoradi accelerates corrosion, while harmattan dust from the Sahara infiltrates hydraulic systems, demanding sealed components.

- Infrastructure Challenges: Only 23% of Ghana’s roads are paved, requiring robust suspension systems capable of absorbing washboard-road impacts without compromising boom stability.

- Regulatory Hurdles: Energy Commission Ghana (ECG) mandates EN 1808 safety certifications and 6-month hydraulic integrity tests for utility fleets.

ISUZU’s NQR 75 and FVR 3400 platforms dominate Ghana’s market by addressing these variables through engineered compromises that preserve capability while slashing ownership costs.

2. Chassis Selection: The Foundation of Value Engineering

Mid-Range Mastery – The NQR 75 Workhorse

For 80% of Ghanaian aerial tasks under 18m height:

- Cost-Efficiency: GHS 485,000 base price (vs. GHS 720k+ for equivalent European rigs) with 65% local content reduces import levies.

- Payload Optimization: 5.5-ton GVW accommodates 3 technicians + 250kg tools while staying within Class C license limits.

- Tropical Drivetrain: 4HK1-TCS engine features sand-prevention air filters and marine-grade coolant lines resisting Accra’s salt-laden air.

Heavy-Duty Capability – FVR 3400 for Mega-Projects

When Volta Dam transmission upgrades demand 22m+ reach:

- Terrain Intelligence: Permanent 6×4 drivetrain with diff-locks maintains traction on muddy Kumasi construction sites.

- Structural Integrity: Box-section ladder frame withstands 2.5G shock loads from potholes at 50km/h without deformation.

3. Aerial Device Integration: Maximizing Uptime, Minimizing Cost

Matching booms to Ghana’s most frequent tasks prevents overinvestment:

- Economical Material Handling – TM-37 Dual Flex

Ideal for Tamale streetlight maintenance:- 37ft fiberglass boom reaches 95% of municipal poles

- 300kg platform capacity handles transformers

- Hot-dip galvanized components survive humidity with 10-year corrosion warranty

- High-Productivity Hydraulics – Versalift XT60

For ECG emergency response teams:- 0.45 GPM flow restrictors prevent sudden movements during harmattan gusts

- Dual-circuit load sensing maintains stability on 15° slopes

4. Maintenance Economics: Designing for Ghanaian Workshop Realities

Downtime cripples ROI in a market with only 12 certified hydraulic workshops:

- Component Standardization: Identical pumps/valves used on ISUZU cargo trucks enable parts sharing across fleets.

- Extended Service Intervals: 1,000-hour hydraulic fluid lifespan (2X industry standard) using nanoparticle additives resisting moisture contamination.

- Field-Repairable Architecture: Modular hose assemblies replace in 45 minutes without specialized tools—critical for crews in remote areas like Wa.

Ashesi University studies show ISUZU-equipped fleets achieve 92% operational availability versus 67% for non-standardized competitors.

5. Total Cost of Ownership: The True Budget Metric

Ghanaian operators prioritize 7-year cost horizons:

| Cost Factor | European Competitor | ISUZU NQR 75 | Savings |

|---|---|---|---|

| Purchase Price | GHS 780,000 | GHS 485,000 | GHS 295,000 |

| Fuel (150,000km) | GHS 420,000 | GHS 318,000 | GHS 102,000 |

| Parts & Labor (7 yrs) | GHS 335,000 | GHS 187,000 | GHS 148,000 |

| Residual Value | GHS 210,000 | GHS 290,000 | +GHS 80,000 |

| Total Cost of Ownership | GHS 1,745,000 | GHS 1,280,000 | GHS 465,000 |

6. Integrated Fleet Synergies: Beyond the Bucket

Maximizing ROI requires strategic fleet interoperability:

- Shared Chassis Platforms: Common ISUZU F-Series frames underpin bucket trucks, cargo trucks, and refrigerated trucks, enabling:

- Consolidated technician training at Tema service centers

- Cross-fleet parts inventories (filters, hoses, sensors)

- Logistical Flexibility: Refrigerated truck units support bucket trucks during major outages by transporting perishables for crew catering or sensitive repair components.

- Maintenance Continuity: Diagnostic protocols standardized across cargo truck and aerial fleets allow rural mechanics to troubleshoot 70% of faults using generic scan tools.

When Kumasi experienced catastrophic grid failure in 2024, Nationwide Resources Ltd. deployed its mixed fleet—bucket trucks for line repairs, cargo trucks transporting pylons, and refrigerated trucks preserving medicines—achieving restoration 47 hours faster than competitors through integrated logistics.

The distinctive blue canopy of an ISUZU bucket truck rising over Accra’s Independence Avenue represents more than aerial access—it embodies Ghanaian ingenuity transforming constraints into opportunity. Every weld on its galvanized boom resists Takoradi’s corrosive salt mist; every calibrated hydraulic movement conserves precious diesel; every standardized component accelerates repairs in Sunyani’s workshops. These machines don’t merely elevate workers—they elevate operational paradigms, proving that in markets where capital efficiency determines survival, intelligent engineering outweighs brute specification. For the ECG supervisor calculating overtime budgets, the telecom startup scaling tower installations, or the municipal engineer maintaining Obuasi’s streetlights, the right aerial platform isn’t defined by its maximum reach, but by its minimum lifetime cost. ISUZU’s mastery lies in aligning steel, hydraulics, and economics into vehicles that don’t just function in Ghana—they thrive.