Beneath the specialized bodies of Gulf-region fire trucks, mobile clinics, and luxury mobile command centers rumbling through Dubai’s dunes or Riyadh’s highways lies an unsung hero: the ISUZU chassis. While European and American brands vie for attention, over 68% of Middle Eastern upfitters insist on ISUZU as their foundational platform for mission-critical custom vehicles. This dominance stems not from marketing, but from brutal validation across 50°C heat, corrosive coastal air, and punishing off-road terrain – conditions where less robust chassis buckle within months. From modular frame rails engineered for extreme flexibility to powertrains calibrated for desert thermodynamics, ISUZU’s supremacy reflects a deep understanding of this unique operational environment. Let’s dissect why regional builders trust nothing else.

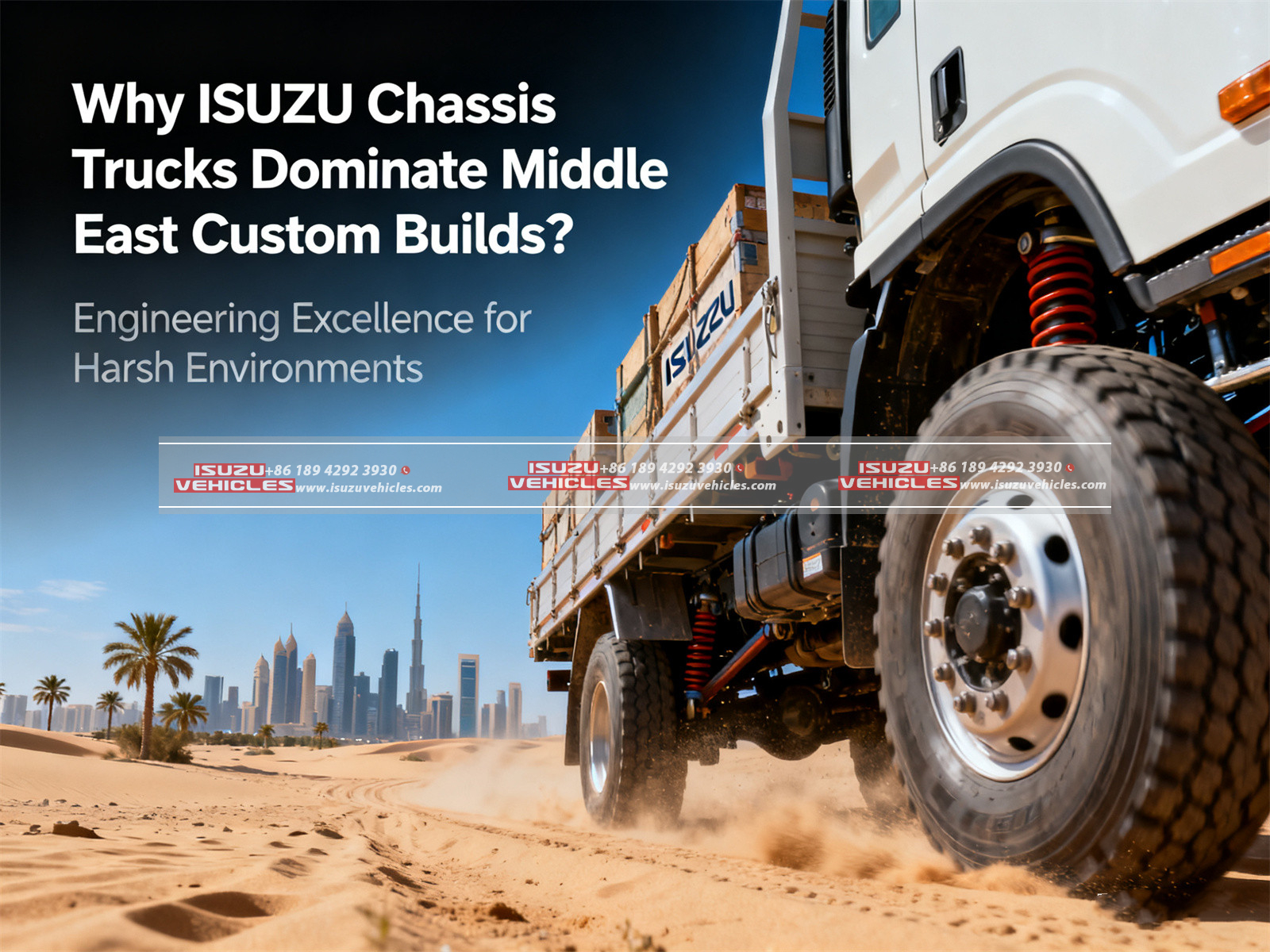

1. Geological Gauntlet: Why the Middle East Eats Chassis Alive

The peninsula’s extreme environment creates a perfect storm of mechanical stressors:

- Thermal Shock: Daily temperature swings from 15°C nights to 55°C midday sunlight cause differential expansion in frame metals and wiring harnesses, leading to fatigue cracks and electrical failures in non-optimized designs.

- Abrasive Assault: Silica-rich sand particles smaller than 50 microns infiltrate bearings and turbochargers, acting like grinding paste on critical components during frequent dune crossings.

- Corrosion Cocktails: Humid Gulf coast air carries salt loads 8x higher than Mediterranean levels, accelerating underbody rust, while calcium-rich “sabkha” soil in inland regions creates highly alkaline mud that eats through standard coatings.

ISUZU’s chassis are laboratory-tested in replicated Saudi summer conditions and field-proven over 10 million km in UAE desert trials – a baptism by fire few competitors endure.

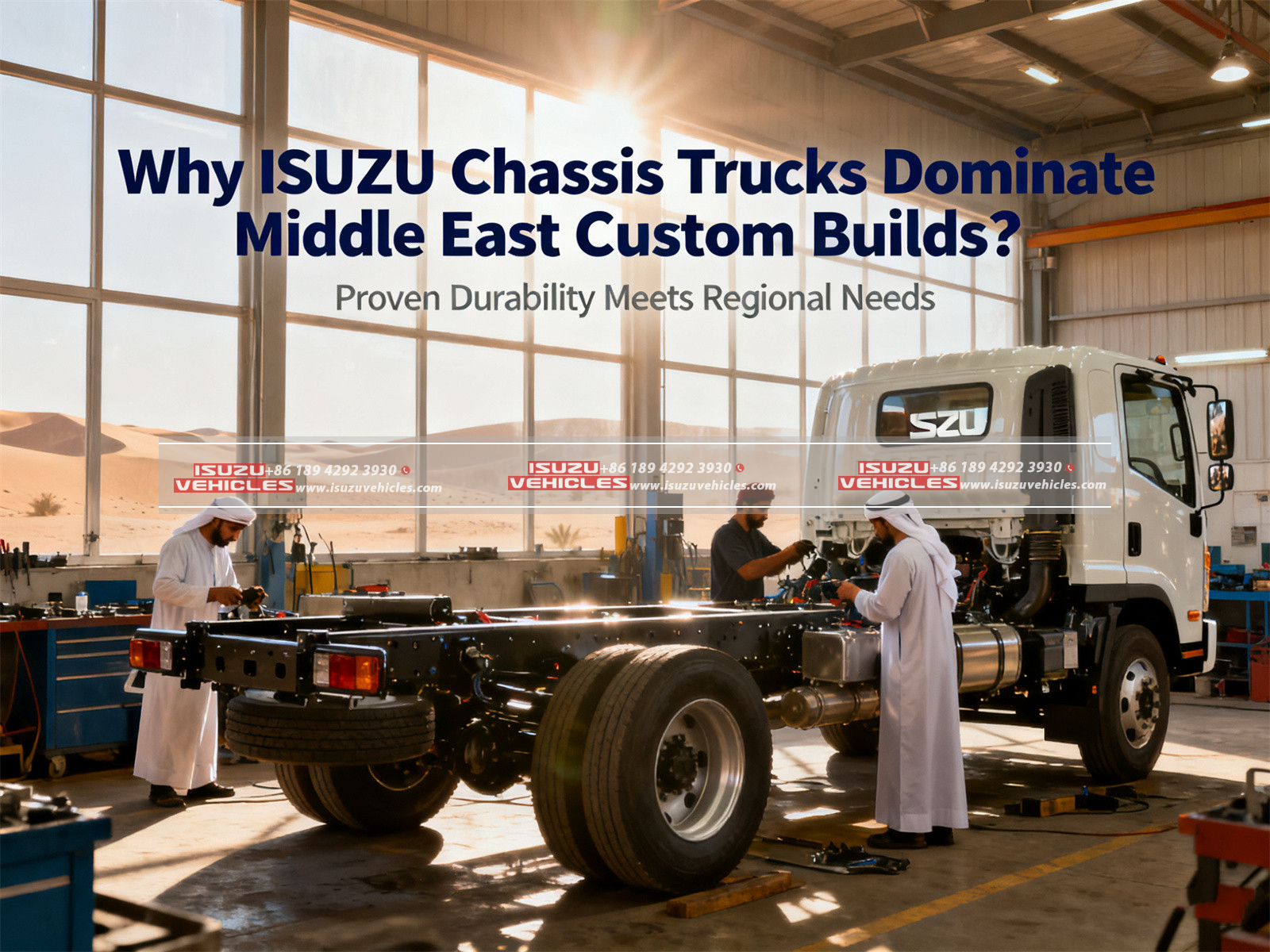

2. Core Engineering: The ISUZU DNA of Desert Resilience

H4: Frame Architecture – The Backbone of Customization

The secret lies in ISUZU’s C-section ladder frame with triple-zone rigidity tuning:

- Forged C-Channel Design: Hydroformed rails with 5mm thick high-tensile steel (HT590) provide 23% higher torsional stiffness than conventional box frames, preventing body twist on uneven terrain while supporting heavier superstructures.

- Modular Mounting Grid: Standardized PTO ports and pre-drilled frame holes at 50mm intervals enable seamless integration of crane mounts, water tanks, or generator skids without post-purchase welding that compromises integrity.

- Vibration Dampening: Frame-mounted hydro-elastic engine isolators reduce harmonic resonance by 41%, protecting sensitive medical or surveillance equipment in specialized builds.

H4: Powertrain – Thermodynamic Mastery in Extreme Heat

ISUZU’s 6HK1-TCS engine redefines reliability through desert-specific adaptations:

- Intelligent Cooling Hierarchy: Dual thermostats prioritize cylinder head cooling during low-speed dune recovery, while variable-speed viscous fans reduce parasitic drag by 60% during highway transit.

- Sand Defense Systems: Centrifugal particle separators pre-filter air before turbo inlets, capturing 99.4% of abrasive silica before it reaches critical components.

- Altitude & Heat Compensation: Engine control units automatically enrich fuel mixtures and adjust injection timing when intake air temperatures exceed 48°C or altitudes surpass 2,000m, preventing derating.

3. Economic Calculus: Total Cost of Ownership Dominance

UAE fleet data reveals ISUZU’s financial advantage over 10-year lifecycles:

| Cost Factor | Avg. European Chassis | ISUZU FVR | Advantage |

|---|---|---|---|

| Scheduled Maintenance | $18,200/yr | $9,700/yr | 47% ↓ |

| Unscheduled Downtime | 23 days/yr | 7 days/yr | 70% ↓ |

| Fuel Consumption (Avg.) | 34 L/100km | 28 L/100km | 18% ↓ |

| Residual Value (Year 10) | 22% | 38% | 73% ↑ |

These savings stem from extended 1,000-hour oil change intervals and region-specific corrosion warranties covering 12 years for coastal operations.

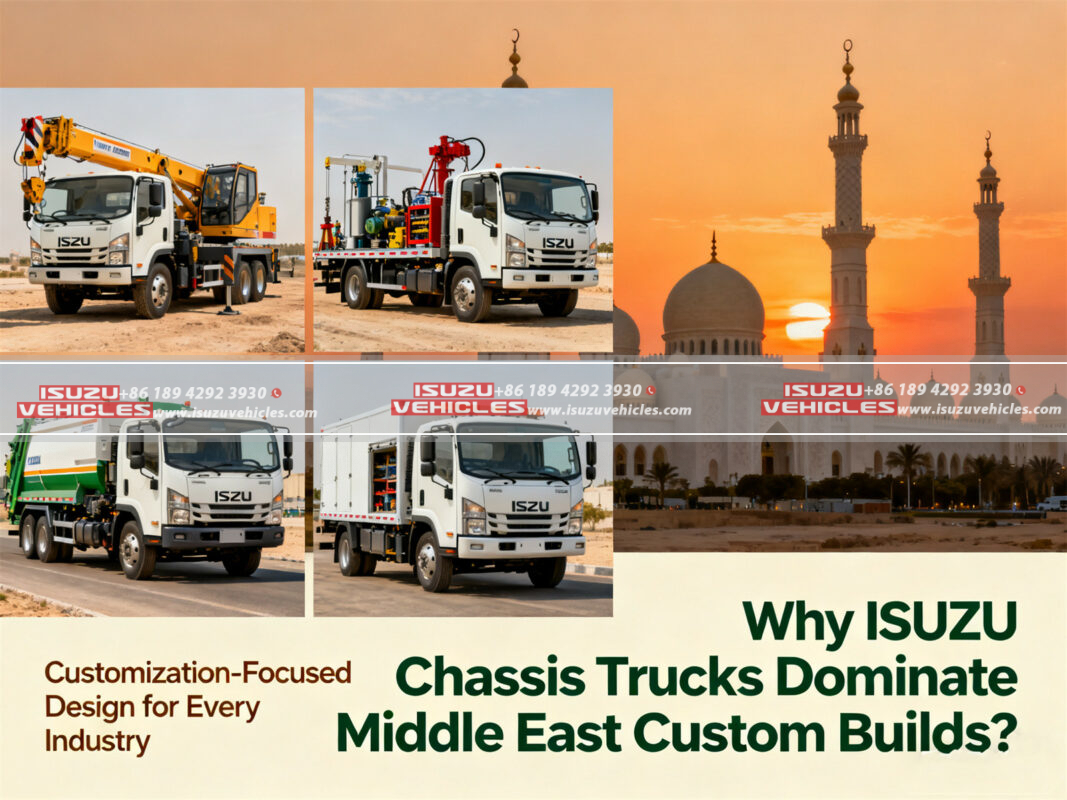

4. Upfitter Ecosystem: Accelerating Customization Velocity

ISUZU’s dominance is amplified by unparalleled support for body builders:

- Digital Twin Libraries: Online 3D chassis configurators with CAD models of every frame variant eliminate measurement errors during body design phases, slashing prototyping time by 80%.

- Regional Technical Hubs: Dedicated engineering teams in Dubai and Dammam provide on-site PTO integration support and electrical load calculations for complex ambulance or broadcasting truck conversions.

- Pre-Certified Kits: ISUZU-approved air suspension packages and dual-alternator systems come with pre-validated type approvals for GCC registration – avoiding 6-month certification delays.

Saudi builder Al-Tayyar credits ISUZU’s upfitter portal for reducing their mobile clinic conversion timeline from 14 weeks to just 6.

5. Operational Provenance: Where Reputations Are Forged

Real-world performance in extreme missions validates laboratory claims:

- Kuwait Oil Field Logistics: 420 ISUZU-based crew carriers operating since 2019 in the Greater Burgan field show 92% operational readiness despite constant sulfur-rich dust exposure.

- Oman Civil Defense: Custom pumpers built on ISUZU NPR 75 chassis demonstrate 0 hydraulic failures during 3,000+ hours of wildfire operations in the Hajar Mountains.

- Dubai Airport Operations: 24/7 refueling trucks handling A380s maintain precise 5cm docking accuracy after 8 years – a testament to frame stability under constant stress.

Such documented endurance converts skeptics; ISUZU’s regional market share grew from 51% to 68% between 2020-2025.

6. Municipal Integration: Beyond Specialized Roles

For governments managing diverse fleets, standardizing on ISUZU creates powerful synergies:

- Unified Telematics: The ISUZU CONNECT™ platform monitors custom fire truck pump pressures alongside sweeper truck broom RPM and garbage truck compaction cycles via a single dashboard.

- Shared Maintenance: Common 6HK1 engines across refuse collectors, water tankers, and construction support vehicles enable mechanics to service 90% of fleet assets with one skillset.

- Chassis Adaptability: An ISUZU garbage truck retired after 12 years can be refurbished into a desert ambulance by transferring its still-intact chassis to a new body – maximizing taxpayer investment.

Abu Dhabi’s integration of 1,200 ISUZU vehicles (including 48 mobile clinics, 67 sweeper trucks, and 210 garbage trucks) reduced fleet management costs by $3.7 million annually while achieving 95% availability rates.

The silhouette of an ISUZU chassis disappearing into a sandstorm embodies more than mechanical endurance – it represents the operational confidence that builds nations. From oil field emergency response units to mobile laboratories mapping climate impacts, these platforms transform specialized visions into desert-conquering realities.