ISUZU 10CBM Refuse Compactor Truck

High-Capacity Waste Management

Built on the robust ISUZU FVR chassis, this ISUZU 10m³ refuse compactor truck is engineered for large-scale municipal waste operations. With overall dimensions of 8,300×2,500×3,000mm and a 4,500mm wheelbase, it balances maneuverability with payload efficiency. The 18,000kg gross vehicle weight and 9,970kg curb weight ensure optimal load distribution, supported by 295/80R22.5 tires (2+4+1 spare) and a 4×2 left-hand drive configuration for urban agility.

Euro 5-Compliant Powertrain

Powered by the ISUZU 6HK1-TCL engine (6-cylinder intercooled turbocharged), it delivers 240HP @ 2,400 rpm and 760 N ·m torque @ 1,450 rpm, ideal for heavy-duty compaction cycles. The ISUZU/MLD manual transmission (6F+1R) ensures precise gear transitions, while the hydraulic power steering cabin accommodates 1 driver + 2 passengers for crew flexibility.

Part 2: Features

Durable Construction & Compaction Efficiency

The Q235 carbon steel body (5mm floor, 4mm sides/roof) integrates an NM450 wear-resistant hopper and a 4mm high-tensile tailgate for longevity. The compaction plate (5mm steel) achieves a 3:1–6:1 volumetric compression ratio, adaptable to household or dense industrial waste. A 2m³ hopper capacity and progressive ejection plate enable 4.5-minute unloading cycles, minimizing downtime.

Leak-Proof & Safety-Centric Design

Hydraulic tailgate locking and leak-proof rubber seals prevent waste leakage, while manual safety props and anti-dropping valves secure maintenance operations. The PLC control box offers push-button automation for compaction, tailgate, and ejection, with manual overrides for emergency scenarios.

Advanced Hydraulic System

The double-acting hydraulic cylinders and front direction control valve ensure reliable force distribution. High-pressure hoses (4× burst rating) and main safety valves guarantee system durability under 7.79L engine output.

Adaptable Waste Handling

Tailored for diverse workflows, the ISUZU garbage truck supports electrical or manual compaction control, with step-by-step ejection plate movement for precise waste discharge. Optional upgrades include customizable body configurations and enhanced hydraulic monitoring systems.

SPECIFICATIONS

| GENERAL | |

| Make/Model | ISUZU Vehicle/ GC10QL240L5 |

| Drive Type | 4×2 Left Hand Drive |

| Overall Dimension

(L x W x H) |

8,300×2,500×3,000 (mm) |

| Gross Vehicle Weight | 18,000kg |

| Curb Weight | 9,970kg |

| Wheelbase | 4,500mm |

| Chassis Designed | ISUZU FVR |

| Cabin | Hydraulic power steering type.

1 driver+2 passengers |

| Drive wheel(Tires ) | 2+4 and one spare (total 7 wheels) |

| Tire Size | 295/80R22.5 |

| ENGINE | |

| Make / Model | ISUZU / 6HK1-TCL |

| Type | 6 cylinders in line, 4 strokes direct injection, water cooling, Intercooler, Turbocharged |

| Displacement | 7.79L |

| Nominal Power | 240HP (177kw) @ 2400rpm |

| Peak Torque | 760N.m@1450rpm |

| Emission Standard | Euro 5 |

| TRANSMISSION | |

| Make / Model | ISUZU/ MLD |

| Type | Diesel |

| Operation | Manual |

| Number of Speeds | 6F+1R |

| CONSTRUCTION | ISUZU chassis; Body; Tailgate (rear hopper); Ejection/discharging Plate; Compaction Plate; Slide Plate |

| CAPACITY | 10m3 |

| BODY STEEL | |

| Garbage Container | High corrosion resistance Q235 carbon steel, 5mm thickness of body floor, 4mm thickness of side and roof. (equivalent as IS-2062 Grade A or ASTM a36) |

| Hopper Floor | NM450 (similar to HARDOX) wear-resistant, high tensile steel sheet. |

| Tailgate Sheet | High tensile steel sheet 4 mm thickness |

| Compaction Plate | High tensile steel sheet 5 mm thickness |

| TAILGATE (REAR HOPPER) | Tailgate Floor, rear hopper floor extension inside body and side wall.

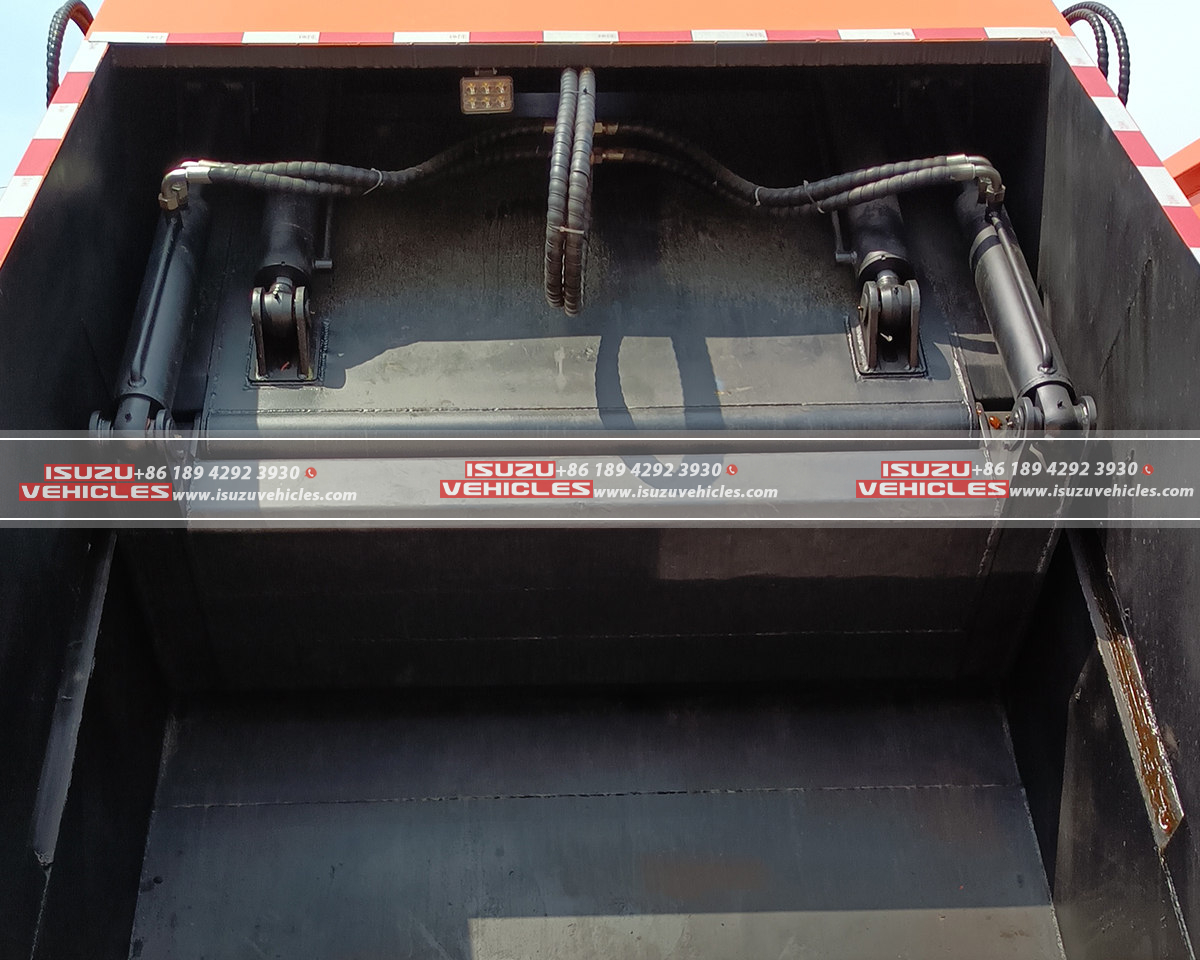

Tailgate is connected to the body with top hinges and opened upwards by means of two units double acting hydraulic cylinders |

| COMPACTION RATIO | The compaction ratio (volumetric) varies between 3: I- 6: 1 according to the characteristics and density of the garbage used in the area (the above-mentioned parameter is valid for household garbage) |

| HOPPER CAPACITY | The garbage capacity of the loading hopper is around 2 m³ |

| SEALING | With a special design, a leak-proof rubber seal between the tailgate and the body |

| LOCKING | Hydraulic locking utilizes the reverse action of two hydraulic tailgate-lifting cylinders. |

| SAFETY PROPS | The tailgate is provided with safety props (manual) between the body and tailgate for safety purposes during maintenance |

| SAFETY VALVE | Equipped with an anti-dropping safety valve on the tailgate and hydraulic lines to prevent sudden falls. |

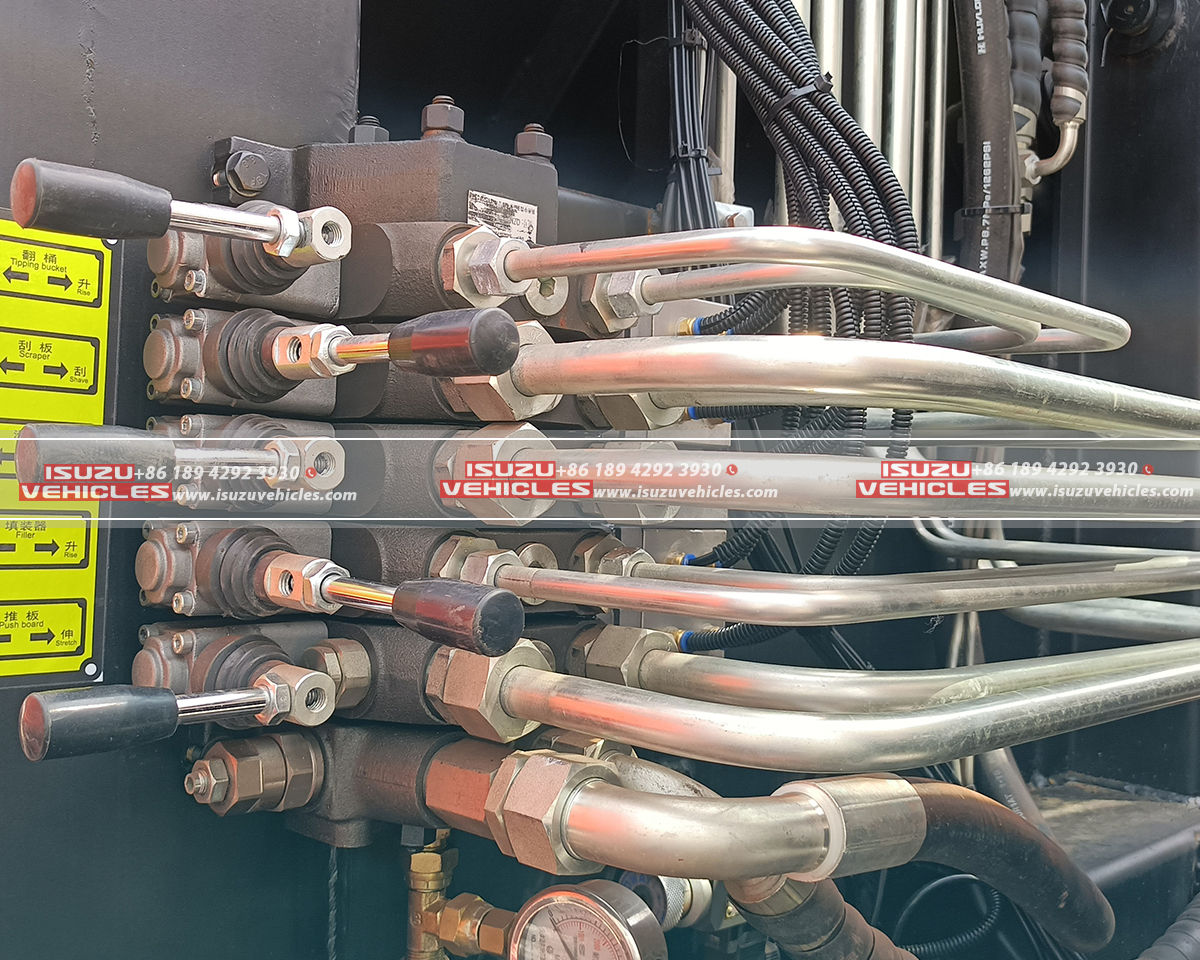

| CONTROL | The system is controlled from the PLC control box, enabling start, stop, 1-cycle, continuous cycles, and rescue activities. The tailgate and ejector controls are in front of the body. All devices for loading control are mounted on the right side, and all are manual controls for safety purposes. Compaction is controlled electrically via push-buttons, and manually in case of |

| DISCHARGE OF GARBAGE | Unloading cycle will last a minimum of 4 minutes and 30 seconds.

Ejection Plate: Movement of the discharging plate (panel) will be step by step in a progressive method (in stages). |

| HYDRAULIC COMPONENTS | FRONT DIRECTION CONTROL VALVE (Front Distributor)

MAIN SAFETY VALVE. All are hydraulic and double-acting. The dimensions of the cylinders’ arc are designed to accomplish the stipulated cycle times and compaction ratio. Hydraulic cylinder pipes & bores included. All high-pressure hydraulic oil hoses have an applicable burst rating 4 times more than the specific system working pressure. |

Reviews

There are no reviews yet.