The ISUZU 24-Ton Foam Fire Truck represents a pinnacle of firefighting engineering, integrating a modular design comprising a reinforced cab, high-capacity water/foam storage tanks (24,000L total capacity), pump compartment, equipment bays, and an advanced foam proportioning system. Built on ISUZU’s globally acclaimed heavy-duty platform, this vehicle combines high-speed mobility (up to 90 km/h on highways), robust power output, and unmatched volumetric efficiency, making it indispensable for fire suppression in high-risk environments. Its operational scope spans metropolitan fire departments, petrochemical complexes, industrial zones, port logistics hubs, and airfield emergency units, where rapid response and large-scale fire containment are mission-critical.

Application: Versatility Across Fire Classes

As the backbone of modern fire brigades, this foam fire truck excels in diverse scenarios through its triple-action suppression capabilities:

- Class A Fires (Solid Combustibles):

- Efficiently tackles wood, paper, textile, and plastic fires via high-pressure water jets (1.0 MPa) and Class A foam that penetrates porous materials to inhibit re-ignition.

- Class B Fires (Flammable Liquids):

- Deploys Class B alcohol-resistant foam to form a vapor-sealing film over hydrocarbons (gasoline, diesel) and polar solvents (ethanol, acetone), preventing flashbacks.

- Class C Fires (Gas Emergencies):

- Utilizes dry chemical compatibility (via auxiliary tanks) to suppress propane, methane, and industrial gas leaks while cooling adjacent structures.

Operational Hotspots:

- Urban High-Rise Fires: 360° articulating monitor with 55-meter vertical reach.

- Industrial Spill Incidents: Foam blanket coverage up to 800 m²/minute.

- Highway Crash Response: Integrated hydraulic rescue tools for simultaneous firefighting and extrication.

Material & Frame: Durability Meets Human-Centric Design

Engineered to withstand extreme conditions, the vehicle’s architecture prioritizes safety, accessibility, and longevity:

Anti-Hazard Protection

- Corrosion Resistance: Aluminum alloy compartments treated with PVDF nano-coating to resist chemical splashes and saltwater degradation.

- Impact Resilience: Carbon steel skeleton (Q345B grade) with modular crumple zones absorbs collision forces while protecting critical systems.

- Ergonomic Accessibility:

- Outward-Swing Tool Doors: 90° hinges with magnetic locks enable single-handed equipment retrieval.

- Non-Slip Step Plates: Laser-cut diamond tread patterns and LED edge lighting ensure safe access in low-visibility scenarios.

Lightweight Structural Innovation

- Hybrid Frame: High-strength aluminum alloy (6082-T6) crossbeams reduce weight by 15% versus traditional steel frames, enhancing payload capacity.

- Integrated Storage Logic: Compartments categorized by response priority (e.g., Code Red Zone for foam nozzles, Code Blue Zone for medical kits), enabling multi-crew coordination without task interference.

Chassis Performance: Power Redefined

The ISUZU 8×4 (chassis) delivers unparalleled reliability through cutting-edge drivetrain and firefighting subsystems:

- Powertrain Dominance:

- 6HK1-TCG61 Turbocharged Diesel Engine: 380 HP @ 2,600 rpm, paired with a 12-speed AMT transmission for seamless torque delivery (1,450 N·m peak).

- Terrain Adaptability: 8×4 with electronic differential locks conquers muddy, icy, or debris-strewn terrain.

- Fire Pump Mastery:

- CB 10/100 Centrifugal Pump: Delivers 100 L/s flow rate at 1.0 MPa, supporting simultaneous operation of 4 foam/water monitors.

- Smart Pressure Modulation: AI-driven system adjusts output based on hose resistance and elevation changes, preventing pressure drops during high-rise operations.

- Operational Endurance:

- 500 km Range: 400L fuel tank capacity for extended deployments.

- Thermal Management: Auxiliary cooling loops maintain pump temperatures below 90°C even during 72-hour continuous operations.

Strategic Advantages

- Rapid Deployment: 0–100% pump pressure achieved in 8 seconds (industry average: 15+ seconds).

- Foam Conservation: Precision metering system reduces foam concentrate waste by 30% versus manual systems.

- Lifecycle Cost Efficiency: ISUZU’s 5-year/500,000 km warranty and modular component design minimize maintenance downtime.

Certifications:

- Compliant with GB 7956.1-2014 (China Fire Truck Standards) and NFPA 1901 (International Fire Apparatus Requirements).

- Eco-certified for Euro VI emissions and REACH-compliant material safety.

SPECIFICATION

| General | |||

| Brand | ISUZU | ||

| Overall dimension | 11900×2540×3680mm | ||

| GVW | 42600KG | ||

| Tare weight | 5090kg | ||

| Emission standard | Euro5 | ||

| Leaf Spring | 4/4 | ||

| High speed | 95km/h | ||

| Chassis | |||

| Model | ISUZU QL5420TZZU2VDHY | ||

| Fuel type | Diesel | ||

| Drive type | 8×4 | ||

| Wheel base | 1850+4575+1370mm | ||

| Tyre specs | 10.00R20 16PR, 11.00R22.5 16PR | ||

| Tyre No. | 10+1 | ||

| Front axle loading | 9000KG+9000KG | ||

| Rear axle loading | 13000KG+13000KG | ||

| Engine | |||

| Brand | ISUZU | ||

| Mode | ISUZU6UZ1-TCG50 | ||

| Cylinder | Inline 6-cylinders, | ||

| Output power | 279kw | ||

| Max horsepower | 380hp | ||

| Output torque/speed | 650N.m/1800rpm | ||

| Gearbox | ISUZU MLD | ||

| Control type | Manually | ||

| Displacement | 9.839L | ||

| Gear No. | 5 forward+2 reverse | ||

| Cab(Crew) | |||

| Seat No | 2+4 | ||

| Air conditioner | optional | ||

| Color | Red or optional | ||

| A refrigerated box in the cabin. | |||

| The floor covering is non-slip and washable. | |||

| Internal roll bar. | |||

| Respiratory protection system in case of distress when a fire front passes over the vehicle. | |||

| Water tank | |||

| Material | Stainless material | ||

| Structure | Crew cab with 4 doors | ||

| Water tanker Capacity | 21400L | ||

| Others | 1 manhole+1 pressure relief device+1 indicator of liquid level+1 outlet with valve | ||

| The interior of the tank is designed in such a way as to ensure the balancing of the means during maneuvers. | |||

| Protection against overflow: No water loss in the event of a full tank and an inclination/slope ≤ 30° | |||

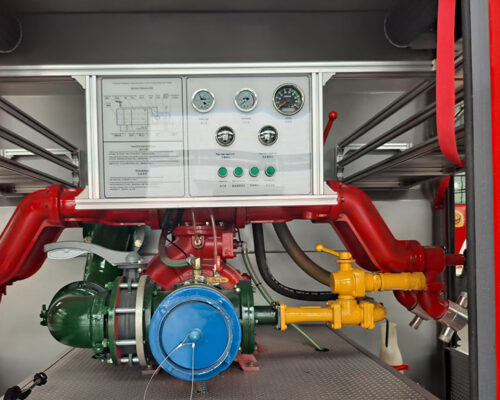

| Foaming agent | |||

| Capacity | 3000L | ||

| Material | Stainless material | ||

| Others | Pressure level indicator. | ||

| Foam concentrate tank filling level indicator. | |||

| Drain valve | |||

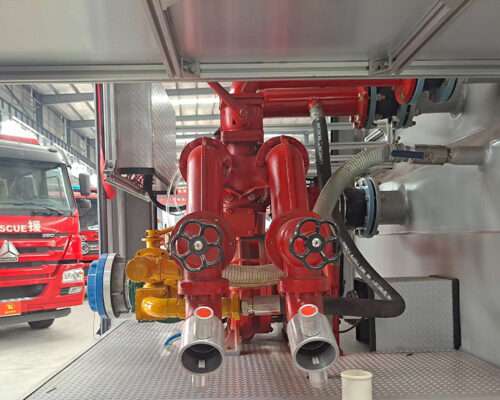

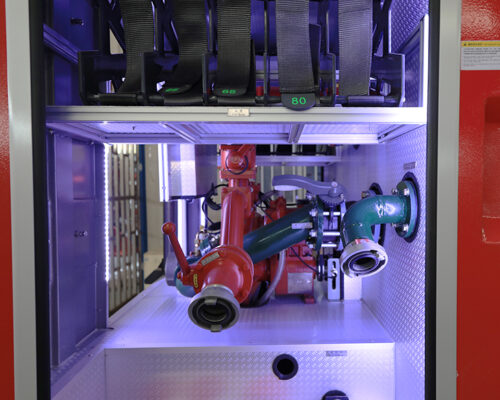

| Water pump

|

|||

| Brand | Shanghai RONGSHEN | ||

| Model | CB10/100 | ||

| Rated flow | 100L/[email protected] | ||

| Pressure | 1.0MPa | ||

| Fire monitor | |||

| Brand | Chengdu WST | ||

| Model | PL8/80 | ||

| Rated flow | 80L/S | ||

| Range | >85m | ||

| Working Pressure | <1.2MPa | ||

| pitch rotation angle | -30~+70(°) | ||

| Horizontal Rotation | 0~360(°) | ||

| Weight | ≤25kg | ||

| Electric system | |||

| Auxiliary lighting | The lighting lamps and the control panel are equipped with lighting, indicator lights, etc. | ||

| Strobe lights | Red and blue strobe lights are on both sides of the vehicle. | ||

| Firefighting light | 35W fire searchlight installed on the rear of the bodywork | ||

| Warning device | Long row of red warning lights installed on the top of the cab | ||

| The control box for the siren is located in the front of the driver. | |||

| List of documents carried in the vehicle | |||

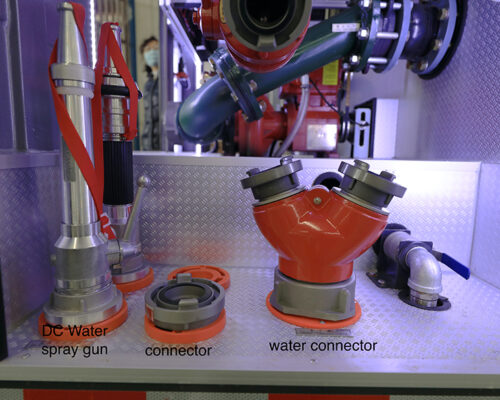

| No. | Name | Specification | Qty |

| 1 | Water pipe(snap type) | Φ100x2m | 4 |

| 2 | Water filter(snap type) | FLF100 | 1 |

| 3 | Water segregator | FII80/65×2-1.6 | 1 |

| 4 | Manifold converging | JII1100/65×2-1.0 | 1 |

| 5 | Fire hose(Insertion type) | 13-65-20 | 6 |

| 6 | Fire hose(Insertion type) | 3-80-20 | 4 |

| 7 | Injection Fire hose | 13-65-5 | 1 |

| 8 | Irregular onterface | 65/80 | 1 |

| 9 | Hose bandage | DT-SB | 4 |

| 10 | Hose hook | 4 | |

| 11 | Ground fire hydrant wrench | QT-DS1;400 long | 1 |

| 12 | Underground hydrant wrench | 860 long | 1 |

| 13 | Water pipe wrench | FS100 | 2 |

| 14 | Multifunction water spear | QZG3.5/7.5;65 | 1 |

| 15 | Multifunction water spear | QHD3.5/7.5;65 | 1 |

| 16 | Fire extinguisher | 3 kg/ABC | 1 |

| 17 | Fire ax | QTF-PF; 810mm | 1 |

| 18 | Fire waist ax | GF-285;390mm | 1 |

| 19 | Rubber hammer | 1 | |

Reviews

There are no reviews yet.