Structure of ISUZU Dry Powder Fire Truck

A dry powder fire truck primarily comprises the following components:

- Chassis: The foundational structure of the vehicle.

- Cab: The driver and operator compartment.

- Compartment: Storage area for equipment and systems.

- Dry Powder Nitrogen System: The core component for fire suppression.

- Water Pump System: Auxiliary system for water-based firefighting.

Dry Powder Nitrogen System: Key Components

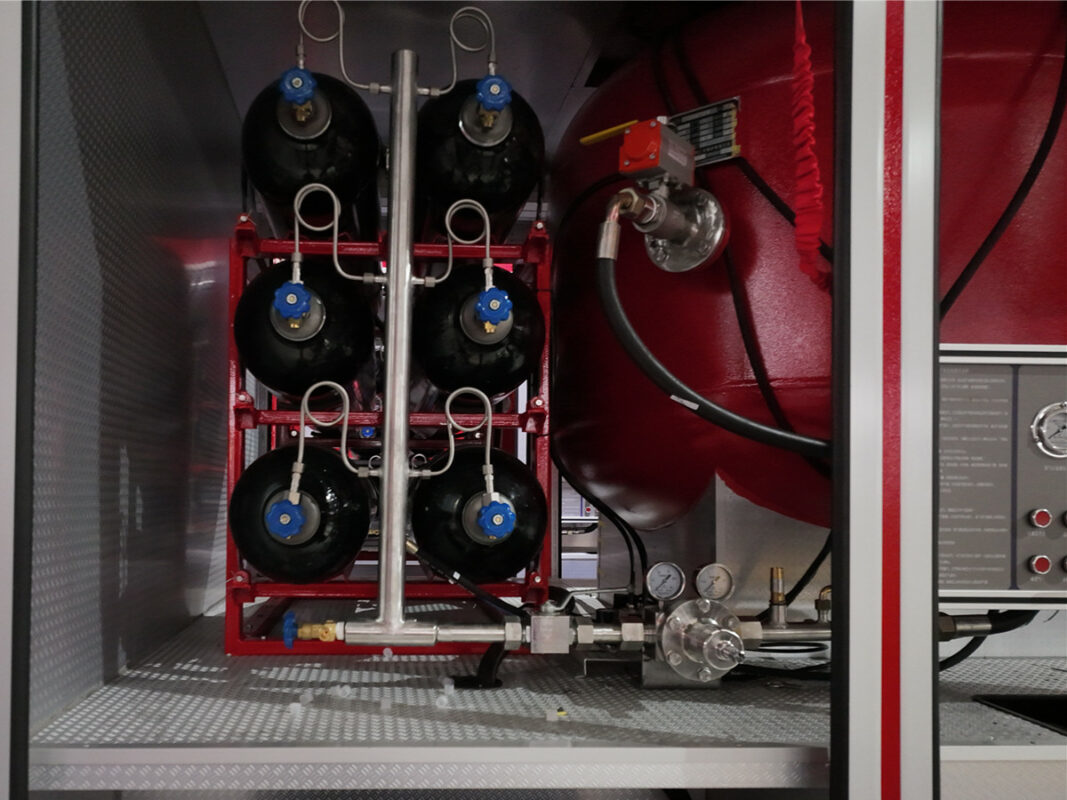

This system is the heart of the ISUZU 6000Kgs dry powder fire truck and includes:

- Nitrogen Bottles

- Function: Provide pressurized nitrogen to propel the dry powder agent.

- Installation: Secured at the rear of the compartment using circlips and anti-loosening rubber pads.

- Dry Powder Tankers

- Function: Store dry powder fire extinguishing agents.

- Design:

- Positioned centrally in the compartment with fixed supports.

- Bottom: Equipped with intake pipes.

- Top: Includes pressure gauge connectors, outlet connectors, and a safety valve.

- Intake Structure: One-way valve to prevent backflow.

- Dry Powder Monitor & Gun

- Function: Adjustable nozzle system for targeted firefighting.

- Components: Monitor pipe, elbow inner casing, positioning instruments, and variable valves for adapting to fire scenarios.

Applications of Dry Powder Fire Extinguishers

Dry powder systems are effective for:

- Class A Fires: Combustible solids (e.g., textiles, paper, wood).

- Class B Fires: Flammable liquids (e.g., diesel, petrol, paint).

- Class C Fires: Flammable gases (e.g., methane, butane).

- Electrical Fires: Suitable for electrical equipment under 1000V.

Working Principle of the Dry Powder Nitrogen System

High-pressure nitrogen from the bottles flows into the dry powder tank via a pressure-reducing valve. This nitrogen acts as the driving force, fluidizing the powder and enabling its expulsion through the monitor or gun.

Operational Procedure

- Pre-Use Checks

- Ensure all valves are closed.

- Inspect the dry powder tank for contaminants and clean the sealing surfaces to prevent leaks.

- Powder Loading

- Fill the tank with dry powder after verifying cleanliness.

- Nitrogen Charging

- Pressurize the tank with nitrogen to activate the system.

- Deploying the Monitor

- Adjust the monitor’s valves and nozzle based on fire conditions.

- Post-Use Maintenance

- Clean the monitor to prevent residue buildup.

- Vent residual gas from the tank after operation.

SPECIFICATIONS:

| Overall Paremeter | |

| Brand | ISUZU |

| Model | QL1250U1QDZY |

| Overall Dimension(mm) | 8465x2540x3500 |

| Total Weight(kg) | 33000 With Full Load |

| Capacity | 2*3000Kgs Dry Powder |

| Cabin | Double Cabin With 6 Seats |

| Highest Speed(km/h) | 90 |

| Fire extinguish capacity(kg) | 2x3000kg |

| Nitrogen vase | 12pcs and 80L of per vase |

| Chassis | |

| Model of Chassis | ISUZU |

| Drive type | 6X4 |

| Wheelbase(mm) | 3985+1370 |

| Engine model | 6UZ1-TCG51 |

| Front/Rear axle loading(kg) | 7000+16000+16000 |

| Tire | 315/80R22.5,1200R22.5 |

| Engine rated Power(hp) | 3 |

| Emission Standard | Euro5 |

| PTO | YES |

| Fuel tank volume(L) | 400(Aluminum alloy material) |

| Transmission | ISUZU ZF(Automatic) |

| The highest speed(km/h) | 90 |

| Cab | |

| Structure | Crew cab with 2+2 doors for optimal entry and exit. |

| Seats | 6 people, |

| Advantage | Flat floors, low step heights, and taller, wider cab doors allow firefighters to get in and out quickly at the scene. |

| Dry Powder Extinguishing System | |

| 1.Dry powder tank | |

| Material | high-strength pressure steel Q345R |

| Quantity | 2 |

| Capacity(kg) | 2*2000kg |

| Rated pressure | 1.6MPa |

| Working pressure | 1.5MPa |

| Residual powder rate | ≤14% |

| 2.Nitrogen bottle | |

| Material | 37Mn |

| Quantity? | 12 |

| Rated pressure(MPa) | 15 |

| Volume(L) | 80/piece |

| 3. Pressure reducing valve | |

| Quantity | 2 |

| Output pressure | 15MPa |

| Max.flowing | 2000m³ /h |

| Opening pressure of safety valve | 1.6 MPa |

| 4.Dry Powder Monitor | |

| Quantity | 2 |

| Working pressure | 1.2-1.4MPa |

| Rated flowing | 40kg/s |

| Range | ≥45m |

| Control | Manual |

| Horizontal rotation angle | 0°~360° |

| Pitch and rotation angle | -15°~60° |

| 5.Dry powder reel | |

| Quantity | 2 |

| Reel hose length | 25mm×40m |

| Injection rate | ≥2.5kg/s |

| Range | ≥12m |

Reviews

There are no reviews yet.